Introduction: Make a 2 Sided, Desktop Infinity Mirror

Most of the infinity mirrors that I've seen are one sided, but I wanted to build one a little bit different. This one is going to be 2 sided and designed so that it can be displayed on a desktop or a shelf. It's an easy, very cool project to make! To me it kind of looks like it could be a Stargate.

If you would like to see a video version of this instructable, you can view it here: https://youtu.be/tkZN4qPhjJ4

Tools Needed:

- Jig Saw

- Jig Saw Blade

- Drill

- 1/4" Brad Point Drill Bit

- 3/16" Drill Bit

- Speed Square

- Wood Glue

- Wood File

- Soldering Iron

- Solder

Parts Needed:

- 1/2" x 3/4" Board

- Wood for the Base

- LED Strip

- Barrel Plug

- 12 VDC Power Supply

- Plexiglass

- One Way Mirror Window Tint, Silver

- 1/4" - 20 1" Long Bolts

- 1/4" - 20 Nylon Lock Nuts

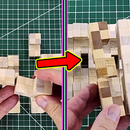

Step 1: Building the Frame

I'm going to start by building the frame. I'm using a 1/2" x 3/4" piece of wood. I measure 3" and mark where I want to cut. While I was doing this step, I was using the combination square wrong so I had to make some adjustments later on. The angle that I wanted to mark off was 20 degrees, then I cut it. Next I sand the cut smooth. For the next piece I turn the board over and follow these same steps. I do this until I have 9 pieces cut. After the pieces are cut I set them up and glue them together. I make sure I get a decent amount of wood glue on each surface. I don't have clamps to hold them together, so I manually apply pressure and make sure the pieces are lined up with each other. Since I don't have clamps, I let these pieces set for about half an hour before attaching the next piece. I continue this until I have it all glued together. As you can see from the finished frame, there is a 10th smaller piece that I added since I got my angles wrong.

Step 2: Attaching the LED Strip

I want to make sure the LED strip is even on both sides of the frame so at the top I mark the middle of the frame, which is where I'm going to start attaching the middle of the LED strip. I use hot glue to attach the LED strip to the frame, a couple inches at a time. Be careful when using hot glue, it's easy to get burned, I burned one of my fingers while making this. Try to keep the LED strip as close to the center of the frame as you can.

Step 3: Wiring Up the LED Strip

Now I drill a 3/16" hole in the frame which is where I'm going to pass the power wire through. I'm going to use a barrel plug to make it easy to connect the LED strip to my power supply. The LED strip has positive and negative contact points. I'm soldering the red wire of the barrel plug to the positive point and the black wire to the negative point. It's easier to do this if you tin the wires and contact points before trying to solder them together. Now is a good time to test the LED strip to make sure the solder points are good.

Step 4: Cutting Out the Glass (Plastic)

The next step is to cut out 2 pieces of plexiglass, one to go on the front of the frame and one for the back. Leaving the protective film on the plexiglass, I trace an outline of the frame on it. I flip the frame to the other side to trace out the plexiglass for the other side. I do this because my frame isn't uniform in shape and each side is a slightly different shape. I keep track of which side of the frame matches up with which piece of plexiglass by marking each. I used a jig saw with a fine tooth blade to cut the plexiglass.

Step 5: Tinting the Glass (Plastic)

Next I'm going to tint the 2 pieces of plexiglass. What this will do is limit the amount of light that passes through the plexiglass, causing it to be more reflective. I remove the protective film from the side that's going to be up against the frame. Then I put soapy water onto the plexiglass. When applying the tint, this will help to get the bubbles and wrinkles out of the tint. I use 2 pieces of tape to help me separate the tint from its plastic backing. After removing the backing I lay the tint onto the plexiglass and squeeze out the air bubbles and wrinkles. If you have a bubble that won't push out, carefully lift up the tint to get the bubble out. When cutting the tint, you don't want to cut it exactly the size you want. Cut it to be a bit bigger so that you have some extra to work with. To trim the extra from the edges I use a razor blade and drag it along the edges, being careful to not let the tip of the razor blade scratch the surface of the plexiglass or the tint. I do the same with the other piece of plexiglass. When trimming the edges with the razor blade, you may find it easier to hold the plexiglass tint side down, but either way will work fine.

Step 6: Drilling the Mounting Holes - 1st Piece of Glass (Plastic)

I line up one piece of plexiglass with the frame, tint side down, and then mark 4 spots where I want to drill mounting holes. Using a 1/4" brad point drill bit, I slowly drill the 4 holes. The brad point drill bit works good for this because the sharp point keeps the bit from wandering.

Step 7: Drilling the Mounting Holes - the Frame

I need to make sure the holes line up, so I put the plexiglass in place and use the drill to mark where I want each of the 4 holes in the frame.

Step 8: Drilling the Mounting Holes - 2nd Piece of Glass (Plastic)

I turn the frame to the other side and line up the other piece of plexiglass. Next I put marks where I want to drill holes into the other piece of plexiglass. Again, I slowly drill the 4 holes. One of the holes I drilled too fast, so it kind of messed it up. But it didn't break so it will still work OK.

Step 9: Bolting the Glass (Plastic) to the Frame

I'm going to mount the whole thing together with 1" long 1/4"-20 bolts and nylon lock nuts. I'm putting it all together to test fit everything. I'm attaching the plexiglass tint side in. I get the bolts and nuts tight enough to hold everything snugly, but not tight enough to sqeeze everything together. I don't want to crack or damage anything.

Step 10: Building the Base - Marking the Cuts

Next I'll be working on the stand. I check the length and total thickness of the bottom. I mark one section of the base at half the thickness. I draw the lines where I want to cut this section of the base. I line up the other sections of the base and make marks and draw the lines on those. Now I cut out the sections of the base that I just marked.

Step 11: Building the Base - Gluing the Pieces Together

Just like when I was building the frame, I glue 2 pieces of the base together. I let it set for about 5-10 minutes then carefully clean off the excess glue. Now I need to glue the 2 halves together, but I let them set for about half an hour or so before I did.

Step 12: Fit the Base With the Frame

After the glue on the base dries I put the mirror in place. It doesn't exactly fit, but I just need to file down the edges at an angle to match the mirrors frame. I file for a bit then test fit the frame. I do this several times until I get a good fit that I like. I'm eager to see how it looks so I set it all up and connect the power supply. It looks good so I'm ready to finish this off.

Step 13: Remove the Protective Film

I may paint the frame and base later, but for now I like the way it looks. I take the bolts out and start to remove the protective film. One bit of advice, this is a great time to clean the tint side of the plexiglass before putting everything back together.

Step 14: And That's It!

And now it's all finished! Just a few notes that I haven't mentioned yet. Since I'm using 2 partially transparent mirrors instead of 1 partially transparent mirror plus a regular mirror, you can see all the way through this one. But I think it's worth it because it gives it the 2 sided effect. Also, I decided to put the tint side towards the lights to help protect the tint from scratches and pealing. If you have any other ideas to make this project better, please leave a comment.

If you make a 2-Sided Infinity Mirror, I would love to see the improvements that you make!

Social Media:

- Twitter - https://www.twitter.com/HowDoYouDIY

- Facebook - https://www.facebook.com/HowDoYouDIY

- Instagram - https://www.instagram.com/howdoyou.diy