Introduction: Easy Laser Cut Organizing Wrench Box

Imagine that you are trying to build a piece of furniture, and you need a wrench to tighten bolts. You look in your tool bag and you see a lot of wrenches of all sizes mixed in with your other tools. You start going through the wrenches and test each one to see which one works. Eventually, you found all the wrenches in your bag and tested all of them, but none worked!

You suddenly realize that you misplaced the wrench you need, and now it is lost.

As you can see in the picture above, my tools were a mess beforehand.

That is where this organizing wrench box comes in. I designed a box that will allow you to store all of your wrenches in a way that is easily accessible. On top of that, the wrenches are all on display, so you can figure out exactly which wrench you need without testing each one.

Supplies

Tools:

- Laser Cutter

Materials

- 12" x 19" piece of 1/4" plywood (12 x 19 fits my laser cutter but use whatever will fit in your laser cutter)

- (Optional) Wood glue or any other glue to put together the pieces

- It will hold together without glue but will be stronger if the pieces are glued together

Softwares

- Lightburn (App that connects with Laser Cutter)

- This is the software that connects to my laser cutter (Boss laser) but use whatever software connects to your laser cutter.

- Onshape (Web-based 3D designing software)

Files

- If you would rather, here are the 3D models for all the parts. If you chose this option, you will have to convert them into a file type that your laser cutter can read. Also, if you decide to just use these files, start from step 11 below and follow the rest of the instructions from there.

Step 1: Learn Onshape

This is going to be the most time-consuming step for this build. Once you create an account on Onshape, you will need to learn how to use the software. For this build, you won't need to know how to design super complex things, but knowing how to change the size of different shapes and how to position lines within a sketch will be very helpful.

Here is a link to a series of YouTube videos on how to use Onshape.

Step 2: Create a New Workspace on Onshape

Once logged into Onshape, click on the "create" button in the top left corner and then click on "Document". This will give you a clean space to work.

Step 3: Create the Bottom of the Box

- Create a rectangle that is 80mm x 210mm.*

- Create four boxes that are each 6mm x 42mm as shown in the picture. Make sure they are 2mm away from the top and bottom.

- Extrude this sketch 5.6mm. It should leave the four added boxes as holes..**

- Create a new sketch with the top side of the box as your new face. Create a rectangle 6mm x 21.1mm on this box and make sure it is 2mm from one of the short edges of the box.

- Repeat this step for the other short edge.

- Extrude this sketch as a hole through the entire model.

- Lastly, for aesthetics, fillet all four corners using the fillet button on the top toolbar.

*All measurements in this design are in mm unless otherwise specified

** Anytime you are sizing something to 5.6mm (1/4") it is just the thickness of the wood you are cutting into. If your wood is a different thickness, make sure to size the models to that thickness instead of 5.6mm.

Step 4: Final "Bottom" Product

This is going to be the bottom piece of the box.

Step 5: Create the Short Sides of the Box

- Create a rectangle that is 35mm x 63.3 mm.

- Extrude it 5.6mm

- Create a new sketch and select one of the long sides as your plane. Create a rectangle that is 21.1mm long and that is the same width as the previous rectangle (5.6mm). Place this rectangle in the middle of the side (21.1mm from either end).

- Extrude it 5.6mm

- On both shorter sides, create a rectangle that is 11.667mm long and the same width as the rectangle (5.6mm).

- Extrude both rectangles 5.6mm.

- For aesthetics, fillet the two corners that are not on the side as the long rectangle that you made. (See the image below for clarification).

Step 6: Final "Short Side" Product

This is going to be the two short sides. You will end up laser cutting two of these.

Step 7: Create the Long Sides of the Box

- Create a rectangle that is 5.6mm x 210mm

- Extrude it 35mm

- Create a new sketch on the bottom of the piece and make two rectangles. They should both be the same width as the rectangle you just made and should have a length of 42mm. See the picture above. They should also each be 42mm from the sides.

- Extrude it 5.6mm

- Now create two rectangles on either end as we did in step 3. Each rectangle should be 6mm x 11.667mm and should be 2mm from either end. They should also be centered vertically.

- Extrude them as holes so they go all the way through.

- This is the basic shape of the long sides.

Step 8: First Part of the "long Sides" Completed

This is the basic frame of the long sides. Continue reading to learn how to complete the long sides

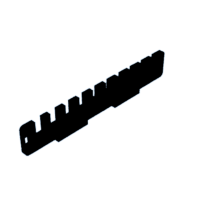

Step 9: Add the Holes That the Wrenches Will Fit Into

This step will take a bit of time because each hole is a different size. The picture above shows where all the holes should be located, and the dimensions of each hole. Keep in mind that all measurements are in mm.

Notice how there are 10 holes. This is because there are 10 common wrench sizes. These sizes are:

- 1/4"

- 5/16"

- 3/8"

- 7/16"

- 1/2"

- 9/16"

- 5/8"

- 11/16"

- 3/4"

- 7/8"

Each hole corresponds to one of the wrenches. The smallest hole is for the smallest wrench (1/4"), and the largest hole is for the largest wrench (7/8").

Once you sketched out all 10 rectangles, extrude them all as holes so they go all the way through.

Lastly, for aesthetics, fillet all four corners using the fillet button on the top toolbar.

Step 10: Final "Long Side" Product

This is what the long side will look like. You will need to laser-cut two of these.

Step 11: Laser Cut the Pieces

- Download all the files as .svg files, and send them to Lightburn or whatever software you are using.

- Adjust the settings on your laser cutter for the type of wood and the thickness. Make sure you are cutting out everything, and not engraving.

- Laser cut 1 "bottom piece", 2 "long side" pieces, and 2 "short side" pieces.

- I recommend laser cutting these pieces onto cardboard first to make sure you made your measurements correct while designing, and also to make sure your laser cutter is set to the correct settings before cutting into real wood.

Step 12: Assemble the Box

- Put one of the side tabs of one of the "short sides" into the hole on one of the "long sides". Make sure all of the holes on the top for the wrenches are facing up. (Use glue to secure it in place)

- Connect the other "short side" to the same "long side" that you used in step 1 by putting one of the side tabs of the "short side" into the other hole on the "long side". (Use glue to secure it in place)

- Make sure both "short sides" are on the same side of the "long side"

- Make sure the bottom tabs on both short pieces are facing down

- Connect the other "long side" to the model by placing the two tabs on the "short sides" into the two holes in the "long side". Make sure all of the holes on the top for the wrenches are facing up. (Use glue to secure it in place)

- CHECK: Make sure the same size wrench hole on one of the "long sides" is opposite the other wrench hole of the same size on the opposite "long side".

- Place the model you just made into the "bottom piece". Make sure the "short side" tabs are fit into the holes on the short sides of the bottom piece and make sure the "long side" tabs are fit into the holes on the long sides of the "bottom piece". (Use glue to secure it in place)

Step 13: You Are Finished! Congratulations!

Place your 10 wrenches into the box, start with the smallest wrench in the smallest hole, and increase the size of the wrench as the holes get bigger.

Now you have a way to easily organize and store your wrenches so you will never lose them again!

Congratulations!

Participated in the

Organization Challenge