Introduction: The Plant Watering Cup

I've found myself killing plants far too often.

To stop this habit, I came up with a simple solution: water my plants when I water myself!

For this project, I modified a cup to do the following:

- Upper half holds water, lower half has the plant and in between is a valve

- When you open the valve, water from the top drips down on to your plant!

- The upper and lower halves are held together with magnets, so you can swap out plants so the others don't get jealous.

Supplies

Here's some of the stuff I used to make the project:

-Tumblers - https://amzn.to/3bteAPo

-Straws - https://amzn.to/3SjG7Dx

-LEDs - https://amzn.to/3P9wDbj

-Battery Holder - https://amzn.to/3Q8elbm

-Silicone sealant - https://amzn.to/3vwhcCQ

-Spring steel wire - https://www.mcmaster.com/9667K29/

-Magnets - https://amzn.to/3OV7aSs

-Masking tape - https://amzn.to/3oNrbjo

Step 1: Cut the Cup

There are three steps to cutting the cups:

- Cut the opening in the lower half for the plant

- Cut the cups in half

- Cut a slot for the spring

I cut masking tape to length and made a rectangular window to act as a cutting guide by attaching it to the lower half of the cup. Dimensions for that opening are:

- Bottom edge length: 3.29"

- Top edge length: 4.01"

- Height (along side edges): 3.5"

I cut the cups in half at just under 4.5" from the bottom.

The spring slot was cut in the upper half of the cup. It was approximately 0.28" from the bottom edge, and the length was about 3/4". I used a dremel with a 1/8" end mill to cut this.

Using a high speed tool with an abrasive cutting wheel will likely melt the plastic during cutting, leaving rough crusty edges. A metal cutting wheel with teeth and slow cutting speed is ideal. I used a mini cut off saw (https://amzn.to/3AFMV6q) and this worked pretty well for me.

Notes:

- This is a double-walled cup, so make sure you cut through both walls

- I ended up filing the edges after cutting to get smoother edges

- I removed the inner wall of the lower cup for this project. When removed, it gives more room to work with.

Step 2: Print the Base Parts

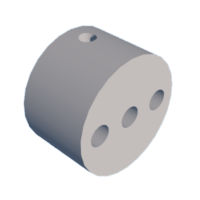

You will need to print 3 parts for this step. Here's what they do:

- PWC-F002 - this is for the upper half of the cup. It's the upper piece in the assembly

- PWC-F007 - v2 - this is for the lower half of the cup

- PWC-F010 - this is for the upper half of the cup. It's the lower piece in the assembly

Step 3: Machine the Spring Holder and Knob

The spring holder (PWC-F008) bolts to PWC-F002, using two 4-40 flat head screws. I machined this from aluminum, as it does see a fair amount of stress when the spring is bent. You could attempt to 3d print it, but I doubt it would be strong enough.

The spring wire itself is installed in the spring holder and held in place with a #4-40 set screw. This is what creates the "pinch valve" in this project. This is just 0.060" spring wire cut to length.

Note: I had to bend it to give a little preload into the straw to make it seal completely.

I also machined the knob - this is pretty much just a cover to go over the spring steel wire. It just makes it more comfortable to use. You could 3d print this if a lathe isn't available.

Attachments

Step 4: Insert Straw

I ran into many leaking issues with the straw connection. To avoid these, don't use hot glue...

I designed an adapter (PWC-F004) as a union to hold the straw, and then that would be joined to the upper base (PWC-F002). Here's how it should be done:

- Cut the straw (https://amzn.to/3SjG7Dx) to an ideal length. I wanted it to extend a little below the lower cup plate

- 3d print PWC-F004

- Pull the straw through the center hole of PWC-F004 and leave about 1/2" of straw above one side of the adapter

- Add your silicone sealant (https://amzn.to/3vwhcCQ) around the straw on the side where 1/2" is sticking out.

- Now pull the straw back thru, so that the 1/2" extension is now flush with the adapter

- This will help seal the surface between the straw and the adapter

Note: To help with sealing, I machined a tapered tube that was inserted in the inside of the straw during assembly. This helped push the straw up against the adapter while the silicone was drying and prevent any leaks.

Attachments

Step 5: Add Magnets to Base Parts

The holes in the base parts are designed for a press fit for the magnets (https://amzn.to/3OV7aSs). Before pressing them in, make sure magnets on top and bottom plates are oriented the correct direction for polarity. Ask me how I know...

Step 6: Assemble Upper Plate Parts

The main assembly process:

- You are basically bolting PWC-F002 (upper) to PWC-F010 (lower)

- I installed LEDs on the lower plate. These are 5mm leds which I wired to a CR2032 battery holder (with built in switch).

- The wiring can run along the trough "ring" as shown in the image.

- The battery holder was glued in place for assembly.

- The three standoffs on the upper plate were tapped #4-40 after the plate was printed

- Don't forget to bolt the spring adapter to the upper plate

- The spring is held in place on the spring adapter (PWC-F008) with a #4-40 set screw

- After this the two plates can be bolted together

- The straw and straw adapter can be fed through the center hole and sealed into place

- After this, the plate assembly is ready to be installed in the upper half of the cup

- After I cut the cup in half, I measured and test fit the plates (and adjusted to size) - the lower plate should be flush with the bottom of the upper cup half (the actual cut edge)

- Once the assembly is pressed into place, I sealed (https://amzn.to/3vwhcCQ) the entire perimeter between the upper plate and the cup sidewall

Step 7: Assemble Lower Cup Plate

The lower cup plate (PWC-F007) can be attached to the lower cup as follows:

- Take the upper cup assembly and place it on a surface, with cup opening facing downward

- Place lower cup plate onto the existing upper cup assembly so that the it snaps into place with magnets

- The magnets should be facing up

- Take the lower cup, turn it so the opening is facing downward and put it onto the plate, so that the plate slips inside the opening

- This should now look like a fully assembly cup, but upside down

- Take your favorite hot glue gun and glue the lower cup to the lower cup plate along the perimeter (on the underside of the plate)

- The only way to access this is through the cut out in the side of the lower cup

Note: make sure you have not already installed the plant pot or plate - it will make things easier.

Step 8: Install the Plant Pot

I originally bought some tiny plant pots from Home Depot, but they were too big. So I ended up designing my own pots and 3d printing them:

- Print the file below

- The underside of the pots fit perfectly with the feature on the bottom of the cup

- I hot-glued the pots to the bottom cup raised feature

Attachments

Step 9: Add a Plant!

Grab your favorite small plant and add it to the pot!

Show your friends how cool you are - you can trade plants with them, too.

Now you'll never forget to water the plant that's in your cup!