Introduction: Air Quality Sensor: Concept to Production

This is the full documentation of the Autodesk University Air Quality Sensor project. Attendees at several events have participated in assembling their own air quality sensor over the past several months. The Concept to Production page will give you more information on how you can use Fusion 360 and EAGLE to create your own products with ease and efficiency, just like we did with this one!

Step 1: "The Factory"

In short, The Factory is a participatory trade show event. In 2017, a colleague at Autodesk had this really cool idea: let's give event attendees a little taste of how things are made using Autodesk software.

It's a hands-on experience where attendees get a kit of parts and assemble a manufactured device to take home. It's a way for attendees to learn about concept, prototyping, and manufacturing with Autodesk software, and walk away with an electronic device that you made with your own two hands.

The device the team came up with was the speaker pictured below. The idea was to showcase some of the different manufacturing methods that were possible with Fusion 360 and EAGLE.

It was a big hit at Autodesk University, 2017, and I volunteered to conduct the event at a trade show in 2018. I noticed a couple of things while running the event:

- People don't really follow instructions. Even though I was on a podium directing everyone, almost no one paid attention. They picked up the parts, started putting the thing together, then started over when they realized the washers were on the wrong side of the trim, the battery carriage was flipped, the circuit board didn't fit, etc. Just like in a real factory, when you leave too much room for error, the factory slows down!

- It's fun to assemble something and take it home, but the thing you make needs to be something you might actually want, so it can't be something you already have. Everyone has a speaker, and it's probably bluetooth or built into a device. An 1/8" analog jack on a cheap speaker isn't likely to be much more than a cool looking paperweight in real life.

So here was my proposal: Let's make something that does the following things:

- It can only be assembled one way. If you skip a step or do something wrong, it doesn't work, or you immediately realize you've made a mistake or skipped a step. This of this as streamlining the production process to keep costs down.

- It's something people might actually want. Air quality sensors are more common these days, but they're still a pretty novel device. Not a single person we talked to at the events already had one. Think of this as betting on demand for your hypothetical product.

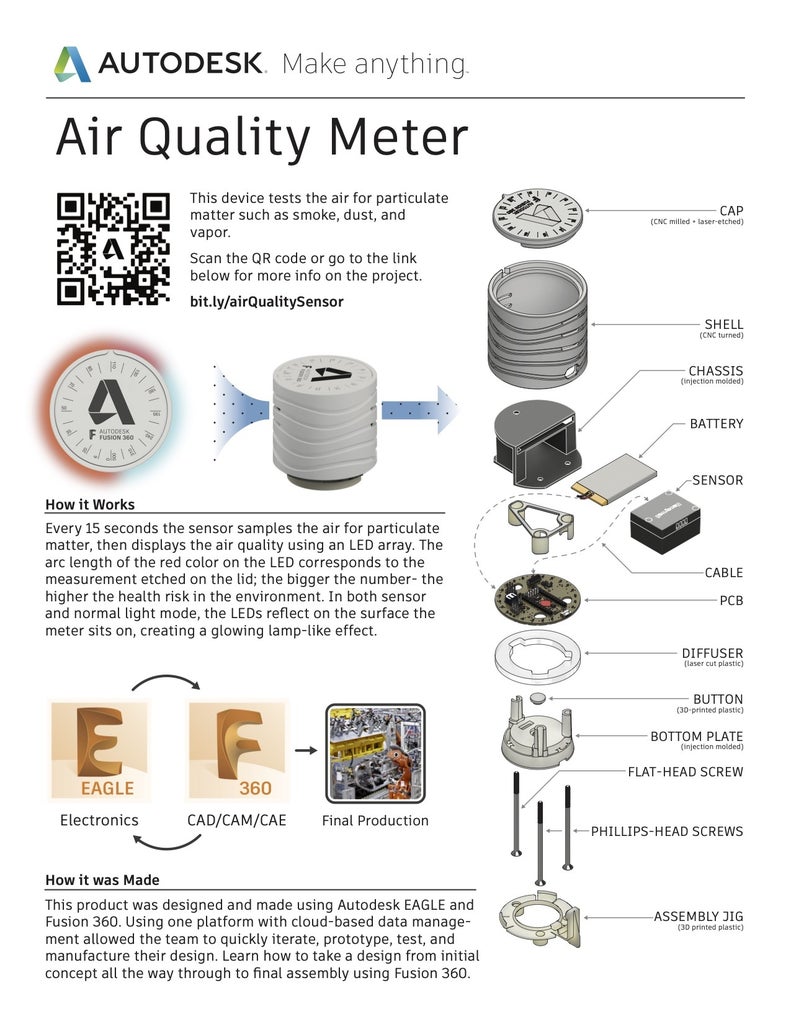

- It showcases a lot of the most important features of Fusion 360 and EAGLE (Think of this as coordinating trades and ensuring that your software can handle complexity and unexpected changes):

- CNC mill and lathe turned parts

- Injection molded parts

- 3D printed parts

- Laser cut parts

- EAGLE PCB design, pushing automatically generated 3D models to Fusion 360 for geometric confirmation, PCB CNC prototyping

- Enclosure and mechanical prototyping

Step 2: The Concept

Sweet Sense

Sweet Sense is a non-profit IOT company that makes products to help impoverished people worldwide. They've got a long list of smart, carefully considered projects that have made a significant impact on the lives of some of the most vulnerable people on Earth.

They had a residency at the Autodesk San Francisco Technology Center, and I was lucky enough to get to spend some time with them.

When the opportunity presented itself for me to come up with a new factory device, I contacted them and we collaborated on the new factory product: an air quality sensor.

This video has no sound

The picture framed device in the video above is the production version of an air quality meter the company developed for long-term use in Africa. They were placed in the homes of people who cook indoors with coal, wood, etc. These fuel sources create a dangerous level of PM2.5 (particulate matter 2.5 microns in diameter, we'll get into that later), and the device gives feedback in the form of e-ink displays standing in for the baby's lungs in the graphic. The idea is to make a clear warning- this is dangerous for your baby, take him outside while you're cooking!

Collaboration

Having spent some time with Taylor Sharpe from Sweet Sense, I approached him about a collaboration. We brainstormed about possible ideas for a device that hit all of the criteria listed previously, and Taylor suggested we make an air quality meter as a consumer product, similar to the one he developed for Africa.

Not only would this be a useful device for anyone (you'd be surprised just how bad your air quality can be when you're cooking, for example), but it could also be instrumental in raising awareness about the problem from a global perspective.

Step 3: Ideation + Prototyping

This video has no sound

Ideation

I worked with a colleague (the gentleman and scholar, Arthur Hursavanakit) to develop the product. Arthur has a lot more experience than I do with production manufacturing, and he was a big help in making sure the enclosure was aesthetically pleasing as well as manufacturable. He was particularly helpful with the injection molding- something I had no experience with prior to this project.

In my experience, ideation is a process best fostered through conversation with hand sketching and white board drawing. It's the fastest way to work through an idea.

We came up with several different options playing with a wave motif, as seen in the images above, but ended up going with something simpler for cost reasons.

Prototyping

Prototyping is a crucial part of any design process. We did most of the prototyping work with 3D printed parts- this is a fast, cheap way to make geometrically process parts that have tolerances that are very close to production parts.

For the electronics prototyping, we used a Bantam desktop mill to make two-sided copper boards for the early versions, then went with OSHPark for prototyping boards.

Step 4: Development

This video has no sound

The development process is in a feedback loop with the prototyping process. It goes something like this:

- Make a prototype >

- Get feedback from the manufacturer >

- Make another prototype based on the feedback >

- Get more feedback from the manufacturer...

We used Fictiv's online platform to get the parts made. They're a virtual manufacturing service that makes it incredibly easy to go from concept to production in no time. The images above are the manufacturing notes they sent back (within a matter of days) that we used to update the design.

Step 5: Production

Version 1: AU 2018 + Pac. Design 2019

Link to view / download: https://a360.co/303uZSJ

The version previewed above is the one we distributed at AU 2019 in Las Vegas, and at Pacific Deign 2019 in Anaheim, CA. This one has a circuit board with two mezzanines- a USB board on top and a Neopixel ring on the bottom. This makes the geometry of the shell, spacer, and bottom plate distinct as compared to version 2 of the device.

The bottom plate on this version also has hole features that were designed to access ports on the circuit board that we ended up value-engineering out of the design after we'd already had the parts injection molded. Long story!

Version 2: AU London 2019, F360 Academy Portland 2019, Future Events

Link to view / download: https://a360.co/30cAsXO

The second version of the product is different from the first as a result of a new PCB that saved a lot of money in production. The new PCB is a single board with components mounted to both sides- no mezzanines. If you joined us at Pacific Design in Anaheim in 2019, at AU London in 2019, or other events in 2019 or later that have yet to be determined at the time I'm writing this, this is the version you have.

The Arduino firmware from the factory version is attached in this step.

Attachments

Step 6: How It Works

Step 7: Open Source

Link to view / download: https://a360.co/31uEtUH

If you weren't able to join in the Factory event and build your own Air Quality Sensor, follow the link above to gain access to the open-source version of the product.

You can download the F360 archive and 3d print the parts on your own.

The files attached here are the EAGLE electronics design files, STL files for printing, firmware, and Arduino code. You can upload the .brd file on OSHPark and order a slick, professional circuit board.

This step also has the BOM (bill of materials) for the project with links to each part.

Special thanks to Taylor Sharpe for putting in the extra time to make an open-source version of the product!

As you can see in the BOM, this project uses an Arduino Itsy Bitsy as its brain, so if you're savvy you can add shields to it and do all kinds of cool things, like connect it to wifi and use the data to track your air quality over time or alert you when it gets above a certain threshold.

Follow this link for Taylor's full documentation of his open-source version on GitHub: https://github.com/TaylorSharpeSS/CEAQL_Air_Quality_Lamp

Attachments

Step 8: Assembly Instructions

These instructions are specific to Version 2 of the product, but given the minor differences between Versions 1 and 2, they will suffice for either product.

Step 9: Events

We've chad the factory experience at a number of different events over the past several months, and it's been a lot of fun. If you were lucky enough to join us, please post a picture of your device and use the #auairqualitysensor hashtag to spread the word!

It'll be back by popular demand at AU 2019, now in color! Also keep your eye out for an awesome new feature