Introduction: Upcycled Bottle Vase

There's a nostalgic retro feel to glass soda bottles. You can bring some of that feel to a simple woodworking project by making an Upcycled Bottle Vase. This simple wood frame holds the bottles firmly in place, and is easy enough to make in an afternoon. This project is a great companion to my free Introduction To Woodworking Class.

Tools + Supplies:

I sketched out a rough idea of what I wanted my bottle vase to look like, but left the design loose enough so I could make changes as needed while I was building.

I started by measuring the bottles I wanted to use in the vase, I used glass soda bottles but anything similar would work. Once I knew the dimensions of the bottle I could plan out the dimensions for the holder.

Placing the bottles next to each other I planned out the spacing. These dimensions were transferred over to a scrap board I salvaged from an old desk.

A section of the scrap board was ripped with a circular saw to make a long plank of wood the width of my bottle holder. Using the measurements taken this plank was cut into 2 pieces that would be the top and bottom of the bottle holder, and 2 pieces which would be the sides of the bottle holder.

Top piece divided into sections, center points of each section marked.

The top piece was measured and divided into 3 sections which were marked in pencil. To find the center of each of these sections I drew a diagonal line from the corners, where they intersect is the center of the section - this is where we'll be drilling through.

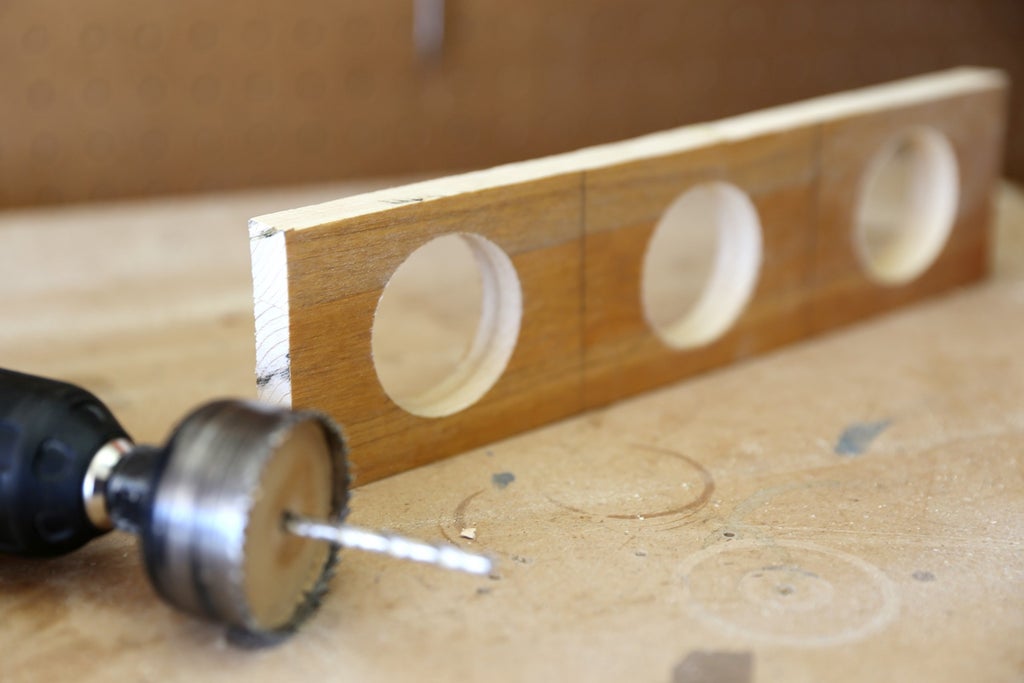

Step 1: Drilling Bottle Opening

To drill an opening large enough for the bottle neck to pass through we'll use a hole saw. Most hole saws have a common drill core that is shared among all the hole saw sizes. The core has a drill bit that acts as the pilot hole and can easily be screwed into a new hole saw if you want to change sizes. Your hole saw might be a little different, but most are assembled the same way.

To determine what size hole saw we'll need first measure the diameter of the bottle where it will pass through the top piece of our bottle holder and then choose the corresponding size hole saw, rounding up since our hole should be larger than the bottle diameter.

Measure bottle diameter

Select hole saw that's slightly larger than bottle diameter

Once you have the right size hole saw assembled set up your work for drilling. Since the hole saw has a long drill bit we'll need to be aware that we'll be drilling through our work and into whatever is below, I chose to work on top of a sacrificial scrap piece of wood.

Once everything is clamped down to your work surface line up the drill bit of the hole saw on your center mark you made on the top piece of your bottle holder and begin drilling into the wood. Even though hole saws are removing the perimeter of your hole and will create a plug when finished drilling all the way through, they are covering a lot of surface area and can get bogged down easily. Go slow with the hole saw and push gently, allowing the hole saw teeth to do the work.

After drilling you should have a plug inside your hole saw from the wood you just cut, this plug can be easily removed by inserting a screwdriver through one of the openings in the side of the hole saw and working it out.

If your work was clamped properly, and you used a sacrificial board underneath, you should have clean holes in your wood.

Step 2: Dry Fit

With the openings made, now is a good time to place the pieces together to see how they fit together. If your measurements were correct your pieces should fit together nicely.

You can make the bottles removable if your vertical pieces of wood are long enough, or you can entrap the bottles inside the wood structure. There's no wrong way to do this, it's just personal preference. I sanded my pieces down so the tolerance was very tight, allowing the option to remove the bottles if enough pressure was applied, but would stay snugly inside the piece on their own.

Step 3: Layout Drilled Openings

To attach the pieces together we'll need to pre-drill the holes, this not only makes screwing the pieces together much easier but also prevents the wood from splitting near the end.

Using a speed square to keep things straight, start by making a line parallel to the end of the top board that is half the thickness of the wood you are working with. I divided this line into 3 segments to give me the location of where the screws will go. To this on the other side and then repeat for the bottom board.

Choose screws that are long enough to penetrate through the thickness of the wood and into the next piece, then select a drill bit that is the same size or slightly smaller than the screws you're using. Keeping your drill perpendicular to the work piece drill your pilot holes all the way though at the marks, remember to use a sacrificial board underneath your work or risk drilling holes into your workbench.

To make sure the screw heads sit flush with the top of the wood we'll use a countersink. The countersink will flare out the top of the drill hole and allow the head to be seated inside the wood. Holding the drill perpendicular to the wood start drilling the countersink into the drill hole slowly, careful not to remove too much material. Check to see if your countersink flare is wide enough by putting the head of your screw into the countersink.

Step 4: Corresponding Holes + Attachment

Because the screws are so close to the end of the wood, and we're drilling into the end grain of the next piece, it's always a good idea to drill pilot holes to prevent the wood from splitting. With the top piece placed on top of the upright section of wood the drill was inserted through the holes we drilled first and into the end grain of the upright, just enough to make an impression.

Once you know where the drill will land on the end grain we can remove the top piece and drill into the end grain to prevent splitting. It's important not to drill too deep into the second piece of wood, otherwise the screw will have nothing to bite into and the screw won't hold.

Align the top piece of wood with the upright section and slowly screw the pieces together, tighten until the screw heads are seated fully in the countersink. Repeat the same for the bottom section of wood. The structure of your bottle vase is now complete!

Step 5: Sanding

To clean up any ragged edges and even up the surface the entire piece was sanded with 100 grit sandpaper and then finished with 180 grit sandpaper to give a nice smooth surface.

Since this bottle holder is upcycled there's a rustic element which doesn't require a perfect sanding job, the important thing is to have a mostly uniform surface.

Step 6: Add Finish

The wood I used was scrap from an old desk, and a little light for my tastes. To help give this bottle vase a little personality I used a little wood stain. This darker stain will cover any inconsistencies in the wood color (since it's scrap), and highlight any dents and marks which gives a nice effect.

I used a rag to liberally wipe the stain all over the wood, allowing it to soak into the wood. After a few minutes I used a clean rag to remove any left over stain. If you want a darker color you can apply more coats of stain in the same fashion, allowing about 20 minutes of drying time between applications.

When I was satisfied with the color I left the wood stain to dry overnight.

Step 7: Display

Once the stain is dry you can put felt pads on the underside of the bottle vase to stop it scratching any surfaces. Insert the bottles and fill partway with water, then add some flowers.

Happy Making :)

Have you made your own version of the upcycled bottle vase? I want to see it!

Happy making :)