Introduction: Patch Welding Tutorial

The effective way to perform patch soldering is drag welding. If you are familiar with drag welding, you can basically use a soldering iron + rosin to complete the soldering of all patches.

We specifically mentioned the tools before welding: It is best to use a flat-head soldering iron with a slanted opening. Considering the anti-static requirements for actual soldering in the future, it is recommended to use a soldering station! (Tools are purchase from https://www.censtry.com/)

Step 1: First Put the IC on the Pad!

Step 2: Press It by Hand After Aligning!

Step 3: Then Use the Melted Wire to Solder the IC's Feet to Secure the IC!

Step 4: All Four Sides Are Fixed With Melted Wire!

Step 5: Evenly Solder the Wire on the Head of the IC Foot After Fixing!

Step 6: All Around the Wire!

Step 7: Next Is the Focus of Drag Welding! Put the PCB Obliquely 45 Degrees, You Can Imagine the Wire on the IC Foot Can Flow Down in the Case of Melting!

Step 8: Put the Tip in the Rosin and Remove the Excess Solder From the Tip of the Tip!

Step 9: Put the Tip in the Rosin and Remove the Excess Solder From the Tip of the Tip!

Step 10: Put the Rosin-coated Soldering Iron Tip Quickly Onto the Soldered Portion of the Slanted PCB Head!

Step 11: The Next Action Will Be the Core of the Entire Drag Welding: Make the Soldering Iron Move As Follows!

Step 12: Repeat the Above Actions to Achieve the Following Effects!

Step 13: Use the Same Method on All Sides!

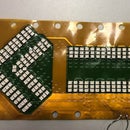

Step 14: Fixed Patch!

Step 15: Sticking Solder

Step 16: Fixed IC Pin

Step 17: Drag Welding!

Step 18: SSOP Operation!

Step 19: The Welding Is Completed!

A lot of rosin on the surface!