Introduction: Rocket Planter

Almost two years ago I made a Saturn V lamp, this time I remixed my own instuctable to create a new one,

one being also a planter!

This project is also a remix of the Modular Snap-Fit Saturn V by RealAbsurdity.

Supplies

- copper wires

- 15x warm white SMD LEDs

- 30mm thick wood plank

- Arduino nano

- toggle switch

- push button

- USB cable

- white heat shrink tubing

- spray primer

- spray paint (white, black, silver)

- paint (red)

- and a plant!

Tools

- soldering iron

- 3D printer

- felt pens

- hot glue gun

- super glue

- masking tape

Step 1: Features

The volume of soil you can put in is a cylinder of 77mm in diameter and 73mm high.

For my lamp project, some people suggested that I add a flickering effect to the exhaust flames, so I placed a button on the back activating this feature.

Step 2: Design Choices

I made the choice not to use cotton, I wanted a simpler look.

The base is made from wood to look nicer than 3D printed PLA.

Step 3: The Fuselage and Engines

Those parts are from the awesome Saturn V model by RealAbsurdity

I applied some changes to the original file :

- scaled up the model

- cut it

- narrowed the edges of the nozzles and the fuselage under the fins

- engraved “USA” four times on the fuselage to help the painting job

- separated the engine part from the fuselage part

- …

Remixed stl files are in the next step !

Step 4: 3D Printing

I used the Creality Ender3 for this project, here are the main settings:

- nozzle temp: 210°C

- bed temp: 50°C

- nozzle diameter: 0.5mm (to reduce printing time)

- layer height: 0.2mm

- infill: 10%

for the exhaust flames I used the vase mode provided by Cura

the total printing time is roughly 24hrs (15hrs for the fuselage)

Follow this link to Cults3D to download the free files.

Step 5: Post-Printing

Once printed, I sanded the fuselage part with 120 grit sandpaper and water, then applied a primer coat, wet sanded again but with 800 grit sandpaper, and finally applied the paint.

/!\ the fuselage part must be water tight because it must collects the drained water! but there was some bridging on the inside, so I applied a hot glue layer on the bottom and a varnish coat over the entire inner surface.

Step 6: Painting

I painted the model according to Apollo XI mission.

I suggest that you paint the white, black, red and finally the silver. Because personally I have done: white, silver, black and red, but at this step, the silver paint was damaged by the manipulation of the fuselage, so I have had to mask and paint it again...

The most important step about painting is masking, indeed if it is well done, the result will be perfect!

To be precise enough, I applied the red acrylic paint into the letters “U”,”S” and “A” using a toothpick, it is a bit time consuming but it could have been done using an airbrush and a really fine masking.

Engines were painted black then I used dry brush technique with silver paint.

Step 7: Exhaust Flames

Those are printed out of white ICE filament PLA by using the vase mode, you will have to print 4 times the [exhaust] and 1 time the [middle exhaust].

After printing, I sanded them using 120 grit sandpaper by doing up and down movement until layers completely disappears.

I could have stop here but I wanted a bit more realism…

On this real image, the exhaust just leaving the nozzle is dark due to non-combusted ergol injected against the inner surface of the nozzle to keep it cool!

So, I colored the flames with water-soluble felt pens to match the reality and mixed up the colors with the finger.

Step 8: Wiring the LEDs

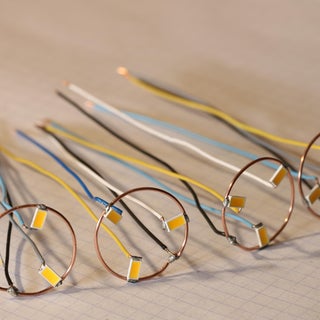

As I said, this lamp has a flame effect but I didn’t want just blinking LEDs … so I came up with an idea, I Placed 3 LEDs into each nozzle so it means 15 LEDs, I powered them through the Arduino PWM output pins, I used pins 3, 5, 6, 9 and 10 each one powering 3 LEDs in parallel (those 3 LEDs must be in 3 different nozzles) by giving a random value of brightness for each pin and updating it each 20ms it gives a nice flame effect.

[As I am not a pro at programming, I encourage you to write a different code for this flame effect and share it, I am sure there are plenty of ways to do this!]

To make things easier, I choose 5 different colored wires to differentiate the 5 output pins.

Personally, I have : light blue, dark blue, white, grey and yellow, you will also need some black wires.

Each nozzle has 3 LEDs into it so 3 different colored wires are passing through (+black)

I made this color code to help you: (each line correspond to an engine, it shows the three colors of wires soldered to its LEDs)

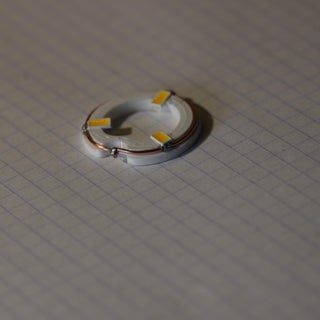

Tool1 will help you solder the LEDs, you will just have to follow those pictures and repeat it 5 times:

solder the (-) of the LEDs to the wire ring.

One of the led rings is wired a bit differently than the others, wires are soldered to the leds but continue on the other side, light blue and yellow are just two wires passing through the ring. On the other side there is a white tubing.

Once it's done, place those inside the nozzles as shown and solder the wires according to the colors.

Step 9:

Step 10: Wooden Base

As for the original design, I wanted a wooden base, I used a 30mm thick wood plank, made a round pocket with a router, cut it into a circle with the jigsaw and then, sanded it.

I drilled three holes on the top, (one for the switch, one for the button, and one for the wires passing through) and one on the back (for the USB cable to pass through).

I printed the second tool [Tool2] and placed it in the center, then stuck round-shaped masking tape as shown:

Then I applied varnish on it:

Step 11: Assembly

- I started by gluing the 5 exhaust flames on the wooden base with super glue helped by Tool2

- Passed the wires of the engines through the middle exhaust, and applied glue on the top edge of the exhausts to join them to the engines part (/!\ remove Tool2 first )

Step 12: Arduino (wiring+code)

Now wires from LEDs are coming into the base so, I screwed an Arduino nano and linked the wires to pins 3, 5, 6, 9, 10 and the black wire to a 10ohms resistor going to the GND pin.

The push button, the toggle switch and the USB cable are also wired.

The code to put in the Arduino is here:

//*******************************

//Rocket Planter

//By SimonRob

//*******************************

int A = 0;

int B = 0;

int C = 0;

int D = 0;

int E = 0;

int ledA = 3;

int ledB = 5;

int ledC = 6;

int ledD = 9;

int ledE = 10;

int brightness = 0;

int button = A5;

bool flame = false;

void setup() {

pinMode(ledA, OUTPUT);

pinMode(ledB, OUTPUT);

pinMode(ledC, OUTPUT);

pinMode(ledD, OUTPUT);

pinMode(ledE, OUTPUT);

pinMode(button, INPUT);

}

void loop() {

if (digitalRead(button)==HIGH){

delay (500);

flame = !flame ;

}

if (flame == false){

digitalWrite(ledA, HIGH);

digitalWrite(ledB, HIGH);

digitalWrite(ledC, HIGH);

digitalWrite(ledD, HIGH);

digitalWrite(ledE, HIGH);

}

if (flame == true) {

effect();

}

}

void effect(){

A=random(100,255);

B=random(100,255);

C=random(100,255);

D=random(100,255);

E=random(100,255);

analogWrite(ledA, A);

analogWrite(ledB, B);

analogWrite(ledC, C);

analogWrite(ledD, D);

analogWrite(ledE, E);

delay(20);

}Step 13: Final Touch and It Is Done !

As on the real one, fins must have letters on them, I found some letters stickers from a VHS kit and drew the outline of “A”,”B”,”C” and “D” (two times) and stuck them on each sides of fins.

All that is left to do is repot the plant, mine is a Crassula ovata “Hobbit”.

Second Prize in the

Remix Contest